Motorhead

lot of small things going on and moving forward here.

It started a couple of weeks ago when I decided to drop in the bearings. They had been sitting in the freezer for a long while and something motivated me to finally start putting the engine back together.

Frost on the inner race

In the oven the cases went. Somewhere around 300 degrees for a few minutes. After the cases were hot, they were taken out and the frozen bearings dropped right in to their races. There was one exception, a needle roller bearing on the small end of the transmission. It took some mechanical persuasion. All of the others literally dropped right in. As the freezing metal quickly warmed in its hot new home, the bearings expanded to their tolerance and stayed in place.

Before being sent off.

The rebuilt crank came next. I stared with the shim side (gear side, clutch side, right side, whatever…) and pressed it in to the case as best I could using a plastic mallet.

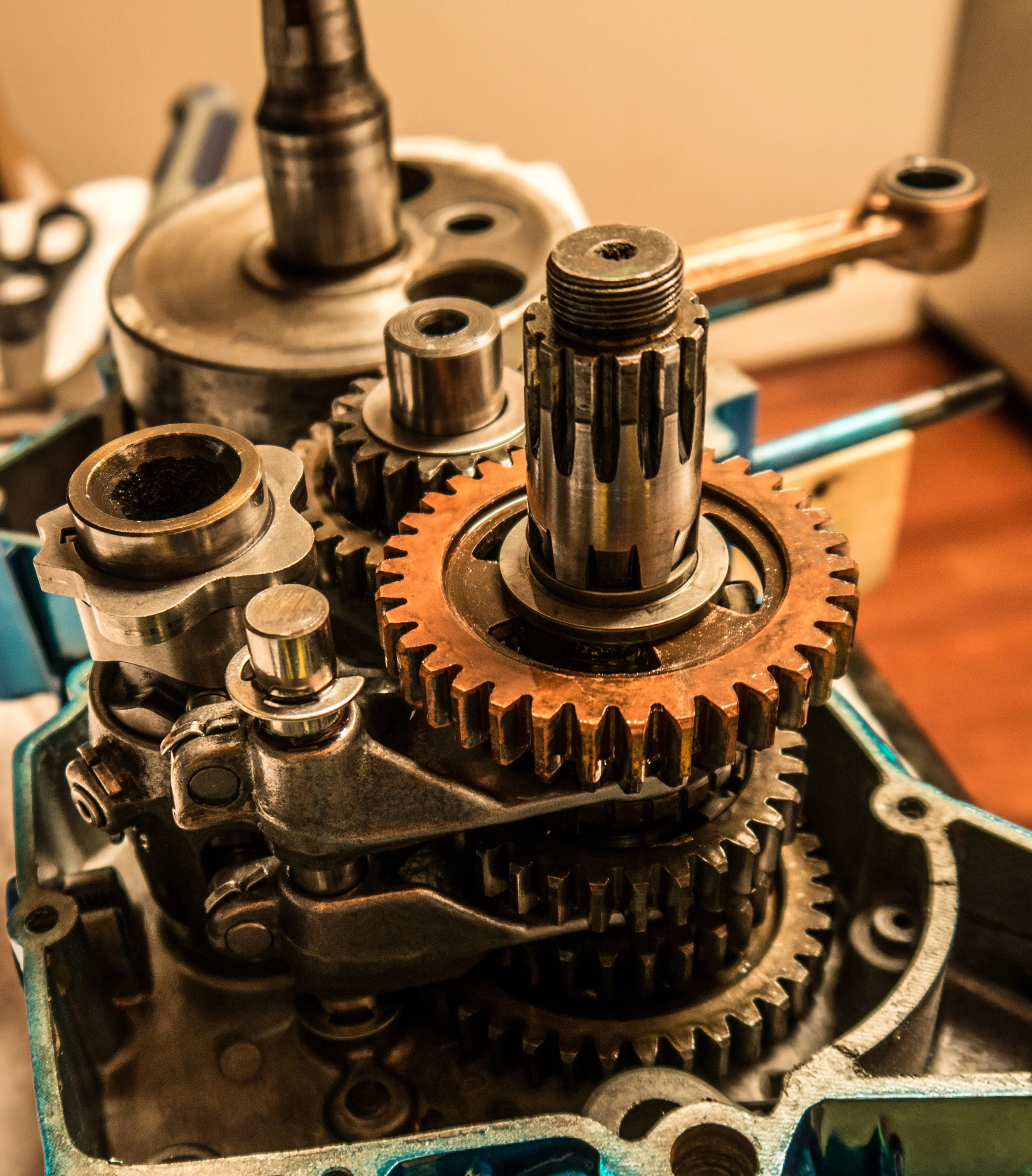

The transmission came out of its foil packet (where I’d placed it some 7 months earlier) and I dropped it in to its place. With a little tweaking and coordination, I was able to get both gear shafts and the shift forks all lined up and in place. This isn’t particularly hard, but it takes some synchronous movement of parts.

Back in college I remember taking apart an old GT80 for the hell of it. When it came to opening the cases…I was blown away. So much stuff. So many parts, so many washers, shims, forks, bearings…I gave up, sold the project.

Rebuilt. New thrust washers and lower bearing (and upper bearing)

After doing 2 of these, they really aren’t that complex or scary. Intimidating they may be..but parts diagrams are helpful and every part is engineered with a purpose. There’s a 2 part retainer and a shim that goes on the transmission. Without those 3 little metal parts, the whole trans can be disassembled down to gears, clips, spacers, and shafts. These tiny parts hold the bronze gear in place.

By far the best advice I ever read was to just put the whole thing in foil, though. It keeps the small parts from falling off and walking away. It preserves everything from accidental bumps, moves, falls. And there is not really anything on the transmission to be serviced (unless you have to rebuild/replace it like I did on the DT2) so it’s easy to set it aside.

unwrapped

Crank is in, trans is in…next step is bonding the two cases with a sealant/adhesive. In japan, they used Yamabond 4 or 6 or some number. The numbers are different formulas. I’ve used a product called motoseal that smells like plastic model adhesive (a wonderful smell) and works well. It’s a semi-drying viscous grey matter that is very very sticky. After running a bead on the sealing surfaces of the two cases, it was time to squeeze them back together.

I’ve taken apart and reassembled motorcycle engines many times in the past without the right tools, and it always leads to serious damage. One of the better investments I’ve made- A case splitter and a crank puller. The crank puller screws on to the magneto side of the crank and pulls the crankshaft on to the case. This process was somewhat hard on the DT2. I’d tighten the tool and pull the crank on and then tap the rear of the case to make sure the transmission drive shaft was coming through the case as well. The DT1 went together with ease. New allen cap screws were used to cinch everything together, the crank was tested for mobility and its centered-ness, and that was that.

There really isn’t a lot inside of the cases.

Internals

With the cases together, the other items can go back on. Stator and flywheel went on with no trouble. With the exception of the countershaft sprocket, there’s nothing else on that side of the engine.

The other side is where all the fun is. Clutch discs, plates, gears, shift mechanisms.

When I took everything apart, I zip tied it together. I know that probably doesn’t make sense, so here’s and example-

The gear that goes on the crankshaft has a rubber o ring, the gear, a washer, and then the nut. My biggest problem when putting these things back together is remembering the order of things.

Clutch discs in background ziptied, clutch baskets/bearings in front

The clutch basket- there’s a spacer, a washer, a bearing, a washer, a race that goes through all of those, an outer basket, inner basket, and then the clutch discs/plates.

When anything of multiple parts came off (and everything has spacers, washers, circlips, etc) I zip tied them together in the order they came off.

This made things 1000% easier when it came time to put it back together 7 months later.

All of the small parts went in zip lock bags and grouped by function. All the clutch hardware went together, all the shift hardware, etc. I had a scare when I saw a small part in a bag and had no idea what it did. I shortly found out that it went on the shift mechanism though, and that tragedy was averted.

So the crank gear and all that goes with it went on first, then the clutch bearing sequence (most complicated part of the engine, I think.) but not the clutch baskets.

You can’t get to the shift mechanism when the baskets are in place. So I hooked up the shift shaft , detent arms, and shift drum. Tachometer idler gear and its washers/clips goes on, clutch baskets go on, clutches and plates go in, clutch activation system goes in (a ball bearing, a rod, and a little cap) and that gets bolted together.

The nylon tachometer drive gear had a catch in it when I was testing it to see how it spun. I decided to take it off and see why…and the drive gear is trashed. I’m pretty sure I did it because I don’t remember seeing it that way when I took it off, but I honestly never looked.

Stripped worm gear

So- I need one of those from eBay. Oil drain and shift drum detent gasket are ordered along with a washer for the shift shaft and a circlip for the oil pump drive shaft.

Other small things like oil pump seals, swing arm bushings, swing arm nut, and some other things are in the mail.

Big needs right now- Tach drive gear, shift shaft washer, oil pump circlip. Once I get those, I can put the bottom end entirely together.

Big needs in the future- Cylinder head bore, piston/rings/pin, fuel petcock, fuel tank.

That’ll make it run.

Not too far away, but I’m starting to realize that these projects are never as efficient as I think they will be. I may need a cheaper hobby. And no one in hell is going to buy a bike with a blue engine.

One day I’ll learn.

For now…more waiting on the mail man.