March 2018

It’s only been almost a year…so…

Updates!

KLX400:

Original owner replaced the fork seals, but the left seal started leaking from the moment I purchased it. I finally got around to fixing it. The modern Showa fork off of this bike is an order of magnitude more complicated than the forks of old, but it was easy enough to take care of. Bike starts and runs great. The temperature sensor is faulty and needs to be replaced, and the bike needs an inspection but aside from that it’s the most reliable bike in the fleet at present.

1971 Pinto:

The pinto was loaded up and brought down here after the last update. Mostly it’s sat waiting patiently. I have made some progress – Floor has been removed, motor has been mounted to transmission, and I’m scheming ideas of how to build a rear sub frame. I purchased a tubing bender and have some sections of 1.5” .120 wall tube ready to be put to use. Hardware for mounting the rear suspension (huge metric studs) is on order. I started doing some body work on the car as well. Because…priorities.

JD2 Model 3 Tubing Bender

1968 Bronco:

Slow progress. The brakes where completed. We made a rear brake line because buying brake lines is a scam. Most early bronco parts are a scam. They’re grossly overpriced. The big win was finding a transmission. I’m of the belief that a car should take some skill to drive. Accordingly, this Bronco was slated to receive a manual gearbox. The motor will be a 2011-2014 Mustang or F150 Coyote 5.0L with around 360hp. Most people who do that swap put in the 6r80 automatic and call it a day. I say that’s fine if you’re a teenage girl, but we want a manual. The bell housing of the 5.0 Coyote modular v-8 is the same as the other ford Modular v-8s (4.6, 5.4). In the late 90s, Ford created the best manual transmission for a truck- the ZF5. It’s a monster of a gear box built for crazy torque and geared for a truck’s work. Short story is that a very small number of these transmission will bolt up to the Coyote 5.0 we’re going to use. Has to be from a small year range, has to have been mounted to a modular v-8 (the 5.4 in this case) and it has to be the 4wd version. An infinitesimally narrow scope. So imagine my surprise when I found a new, factory rebuilt ZF transmission that met those exact requirements. Imagine the further surprise when I saw it was in Elgin, Texas. So I’m the proud owner of a beautiful new baby transmission. Next up- finding the right engine.

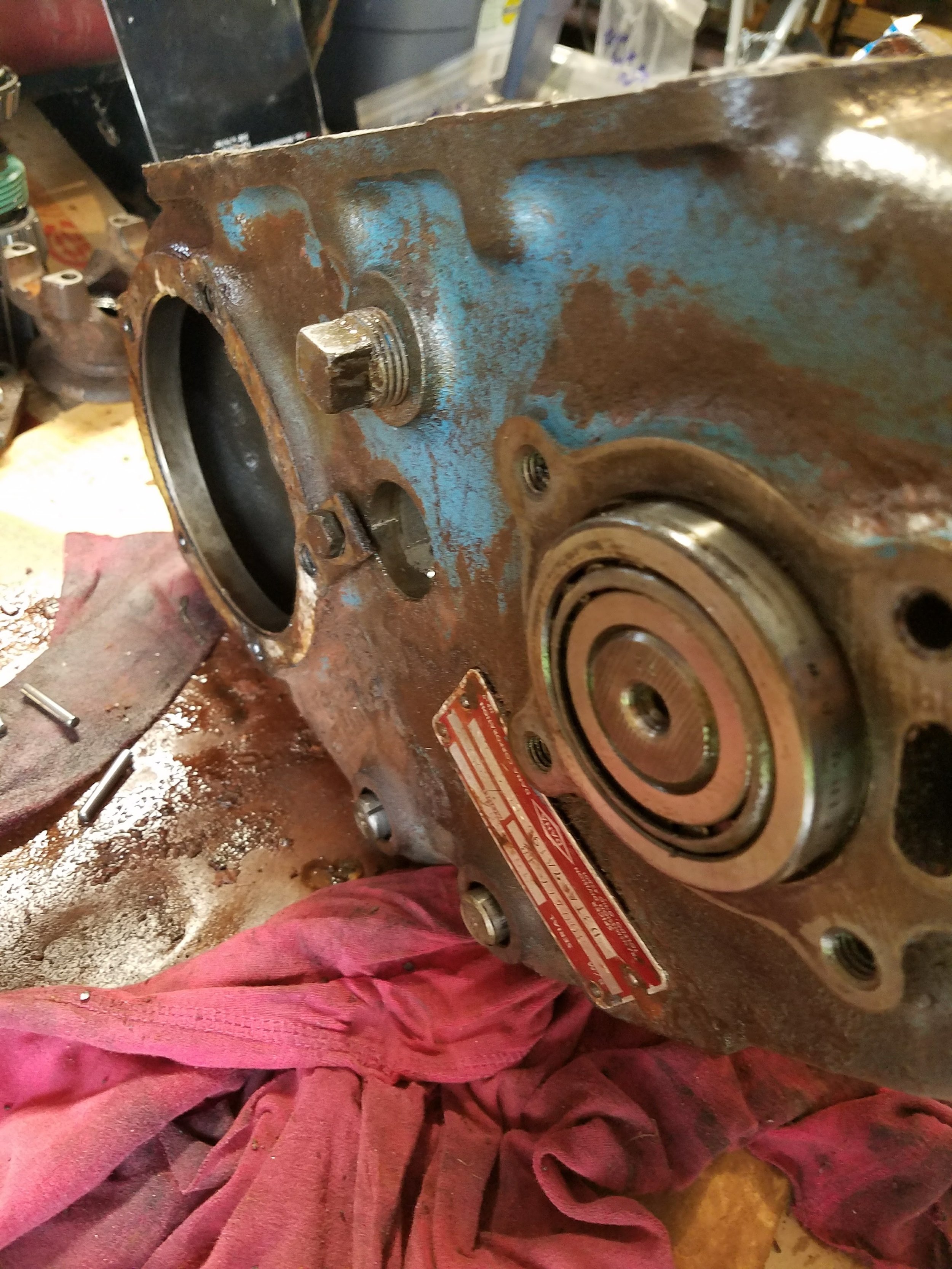

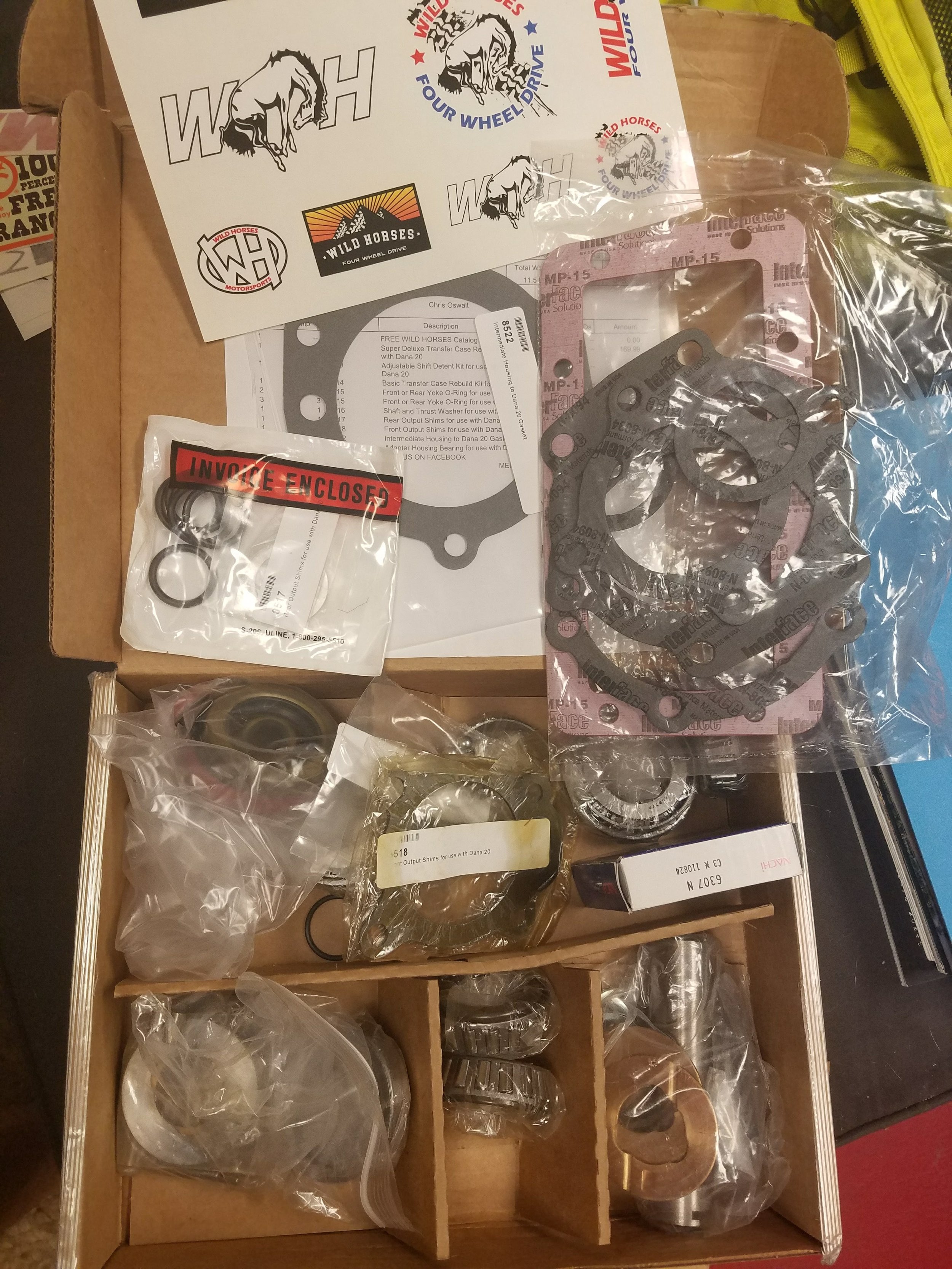

Also in the works with the bronco is the transfer case. Aside from being caked with Oklahoma mud, it wasn’t shifting in to gear reliably when we got the truck. So I began taking it apart. Rebuild kits are cheap and consist of a ton of tapered bearings and loose roller bearings. The hard part of the work is the cleaning. I need to get a 20 ton press to get the new bearings on. Planning on buying that today. There are no instruction which makes putting it back together hard, but I took plenty of photos. The case will get a new shifting set up—a twin stick instead of a single. In this way the front and rear differentials can be controlled independently, When I took the case apart, it was full of ATF instead of gear oil which was curious. This is indicative of a leak between the old automatic C4 and the Dana 20 xfer case. The rebuild will fix all that up. Plus it’s ford blue now, a big win.

RT360-

The guy I paid $300 for this thing told me it needed some wiring work and it was good to go. I took the engine out and opened it up just to have a look, and the motor is trashed. A transmission bearing went AWOL; just grenaded itself in the motor, so I sourced replacement parts on eBay (transmission shaft, shift forks) and bought all new bearings. It’s ready to go together, but I’m leery about using the original case because the bearing race is pretty messed up. Cases are hard to come by on eBay for this model. I may roll with it as it, it depends on if I can get a reliable interface between case and bearings. It should be a tight fit. The cases need to be media blasted. I was going to polish them, but That’s proven difficult and not worth the effort.

BW200-

NEW!!! I found this on a random craigslist search. The guy I bought it from said he got it from a guy who rebuilt it, and then the problems started. Previous owner said the valves were sticking. He had already pulled the motor and had an extra head put on, but it was still causing problems. So I got the rolling frame and a box of engine parts for $800. Maybe a bit steep, but when it’s back together I hope it can sell for twice that. This guy has a blown lower rod bearing. Same problem that the TW200 had. Same problem the KLX400 had. So far I’m $537 dollars in to this one and that should be it. The engine is all ready to go back together. I ported the head (because why not) and put a new crankshaft in it. I wanted to powder coat the whole motor gold, but opted for the original black paint instead. Lots of time cleaning this one up. The good news is I’ve made a handful of videos about it. Here’s the first. Watch as many as you wish.

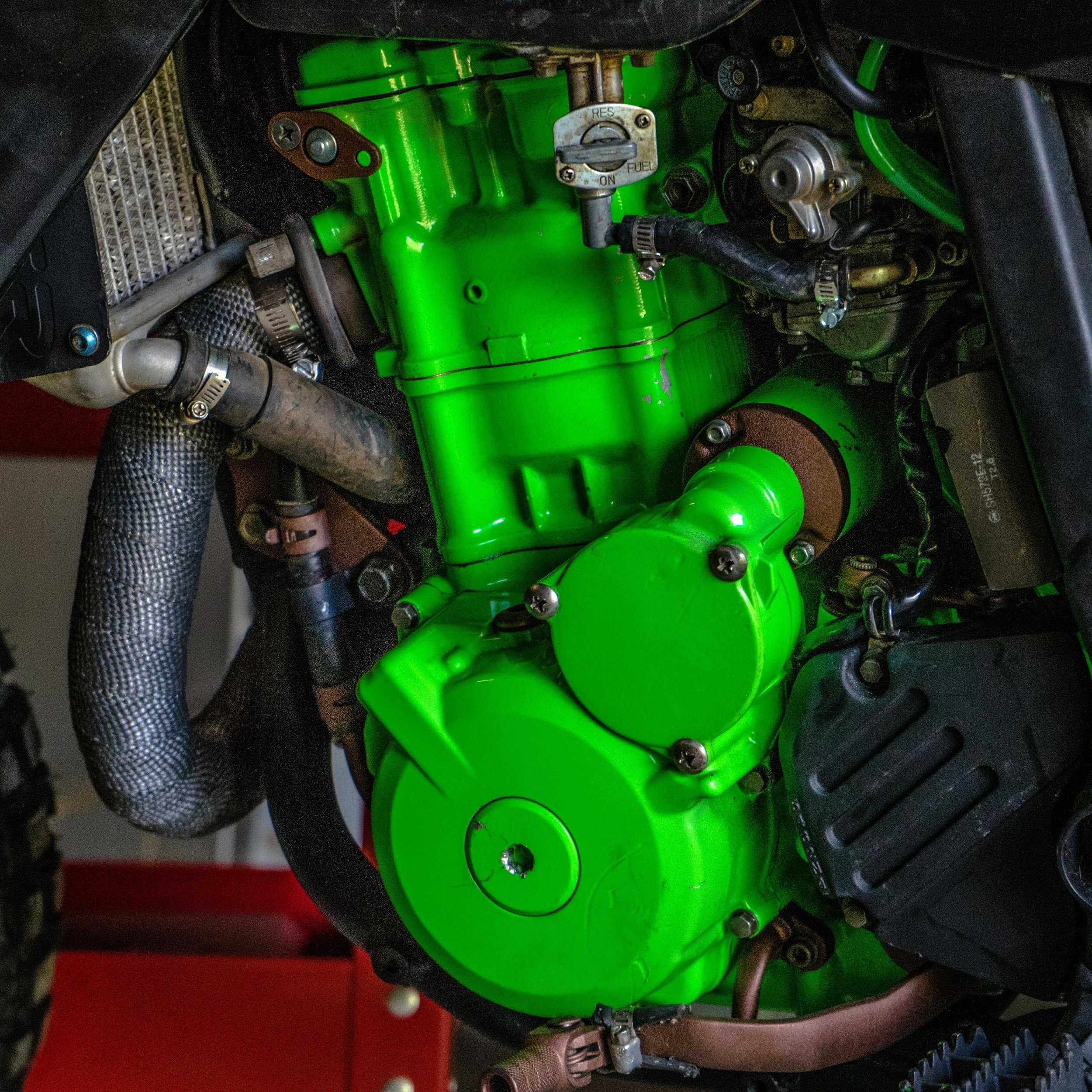

BW350-

this one has come a LONG way. From being a half painted frame and tons of parts, we now have a full roller ready to fire. I’m working on the wiring right now. This is one of the more rare bikes in the collection right now and I want it to be street legal. You can buy an aftermarket light kit for around 350 dollars, but I think that’s absurd so I’m doing it myself. With LEDs. And it’s going to look better. I’ve pieced together brake light switches, hand controls, instrumentation, and all manner of wire and connector to come up with a factory looking set up that integrates in to existing wiring. The bike was never built to handle an electrical load like this, but since its LED I think it will be a nominal strain.

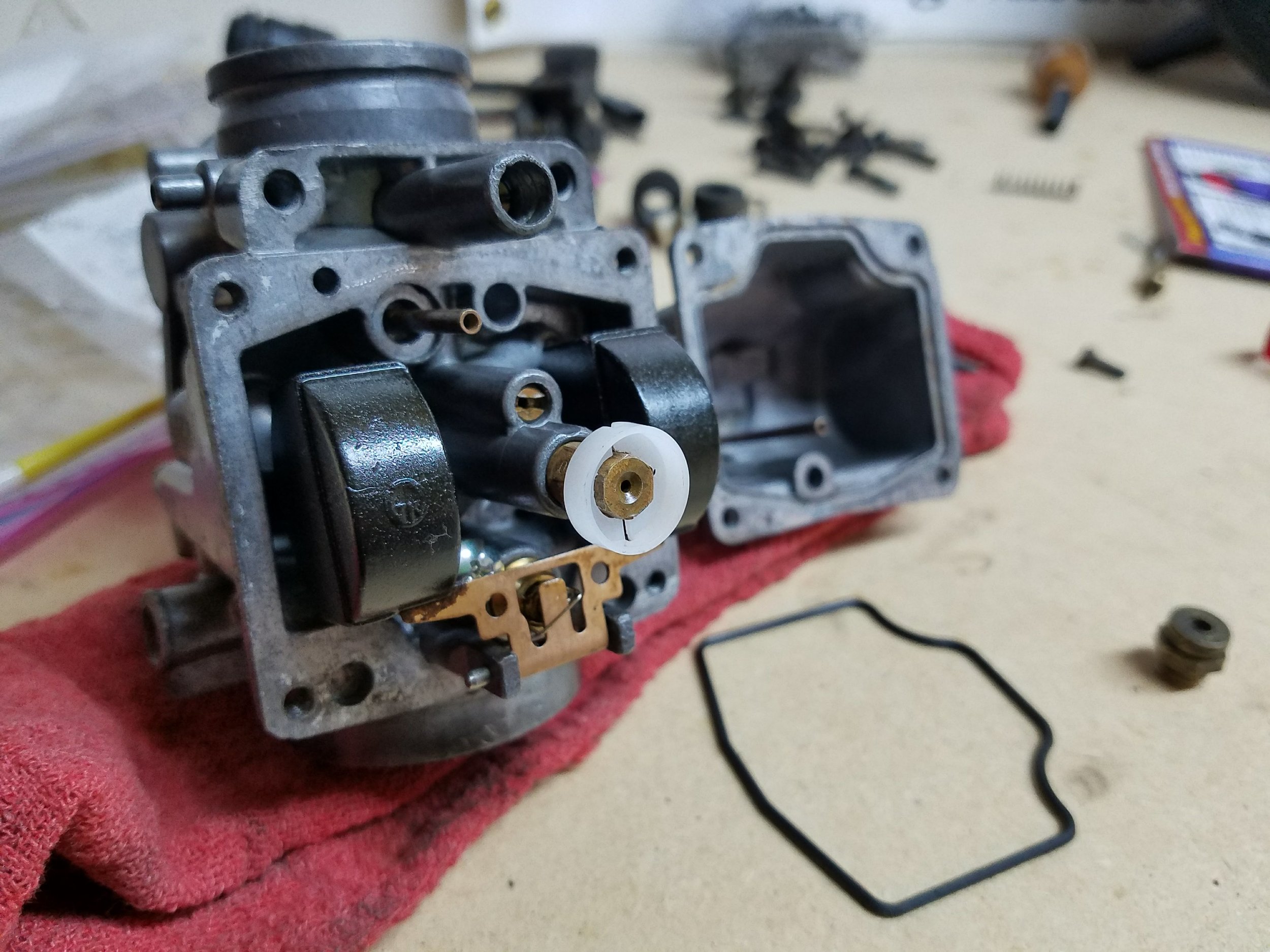

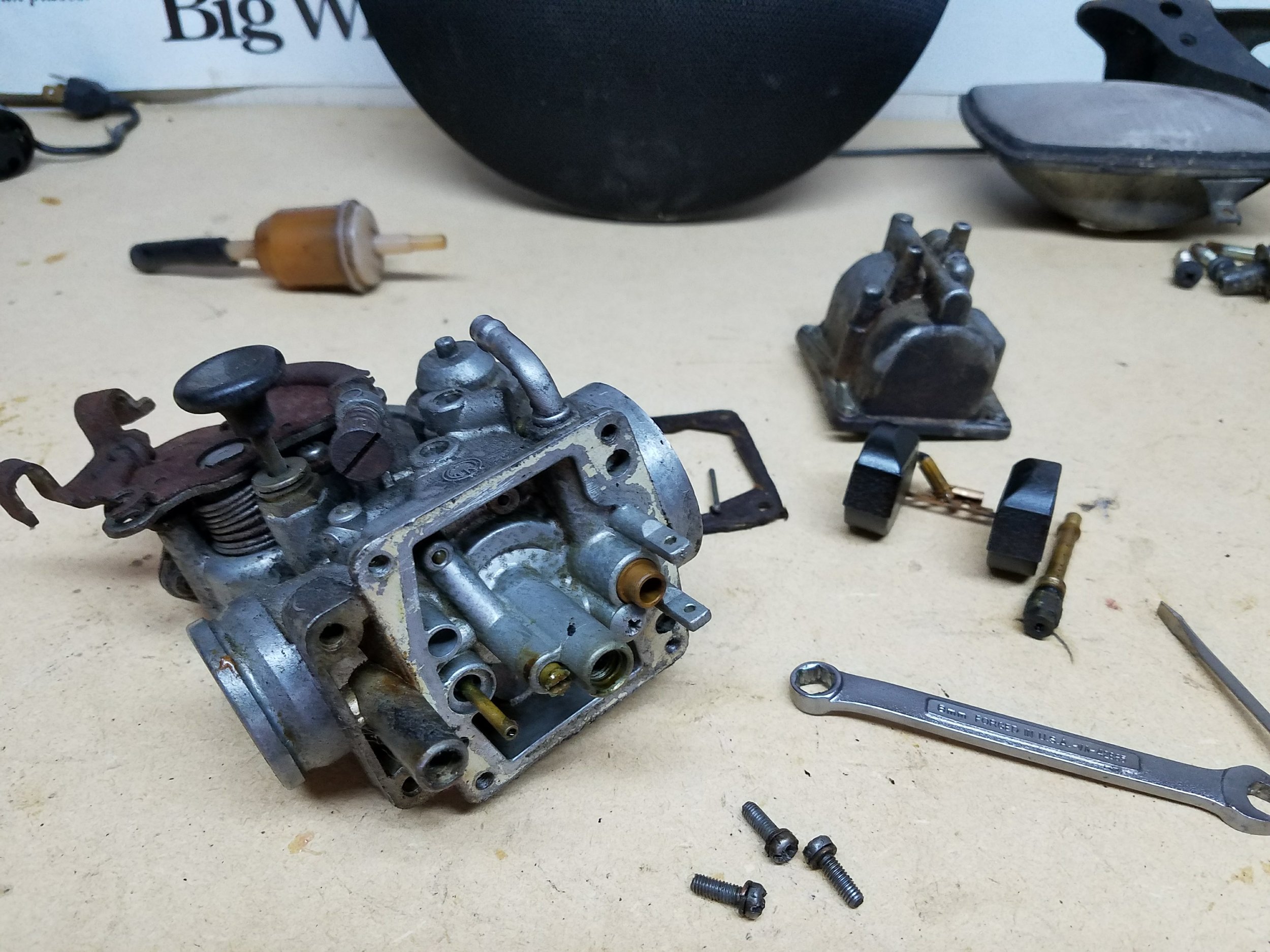

The frame was painted, new steering head bearings were put on (a pain, as the lower bearing was incredibly tightly pressed on, and the new one was very hard to press on as well) front forks were rebuilt with new seals and Automatic Transmission Fluid as fork oil. That’s a tip I’d read on the interwebs, and seems to have worked well. The wheels were cleaned, painted, and had all the bearings replaced. New brake shoes all around. The seat is betting recovered by Diana as we speak. I ordered a plastic kit from a reproduction shop in Michigan. They suck. Their molds are awful, but theirs is the only game in town. The carburetor was rebuilt with a new pump, new gaskets, new jets. It needs a new front tire, but this one is about ready to go.

I think the motor is fine. I did have starting problems. I've been chasing an unsolvable problem with the starter relay. I'm going to hardwired it out of the equation.

The electric starter wouldn't always engage the motor. There's a unidirectional cam that is supposed to engage when the starter turns. I rigged this to work by tightening the circumferential spring around the starter mechanism.

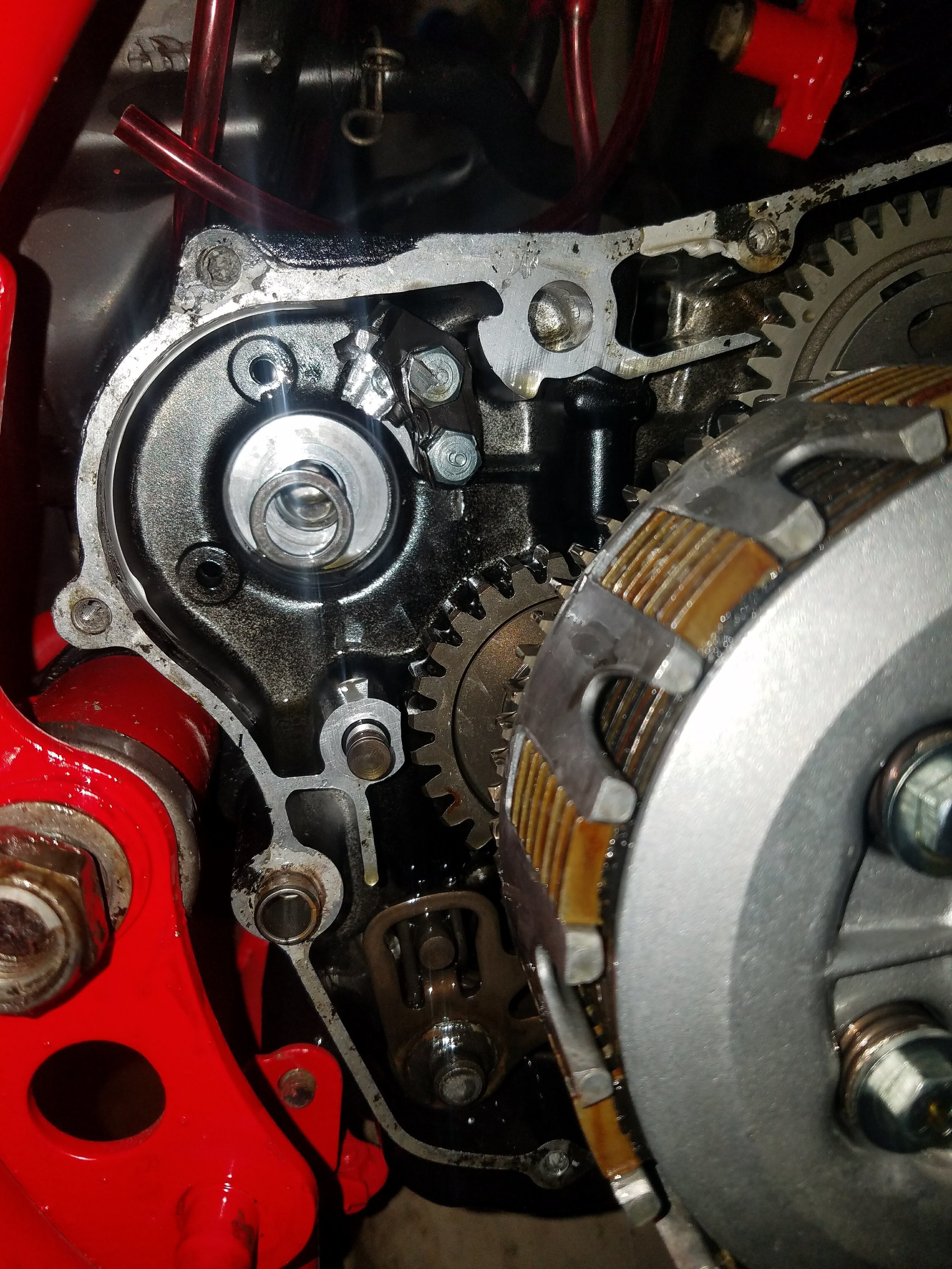

I also noticed the kick starter shook violently when the starter motor was going, and a photo of below shows why. I've never seen it before, but the metal stopping mechanism had sheered off in the case. One bolt completely broken, the other was bent. I was able to drill and remove the broken bolt. It turns out this part is the same used in the old Yamaha DT250s. I happened to have one sitting around, and that's all fixed up and installed with loctite 243.

G4TR-

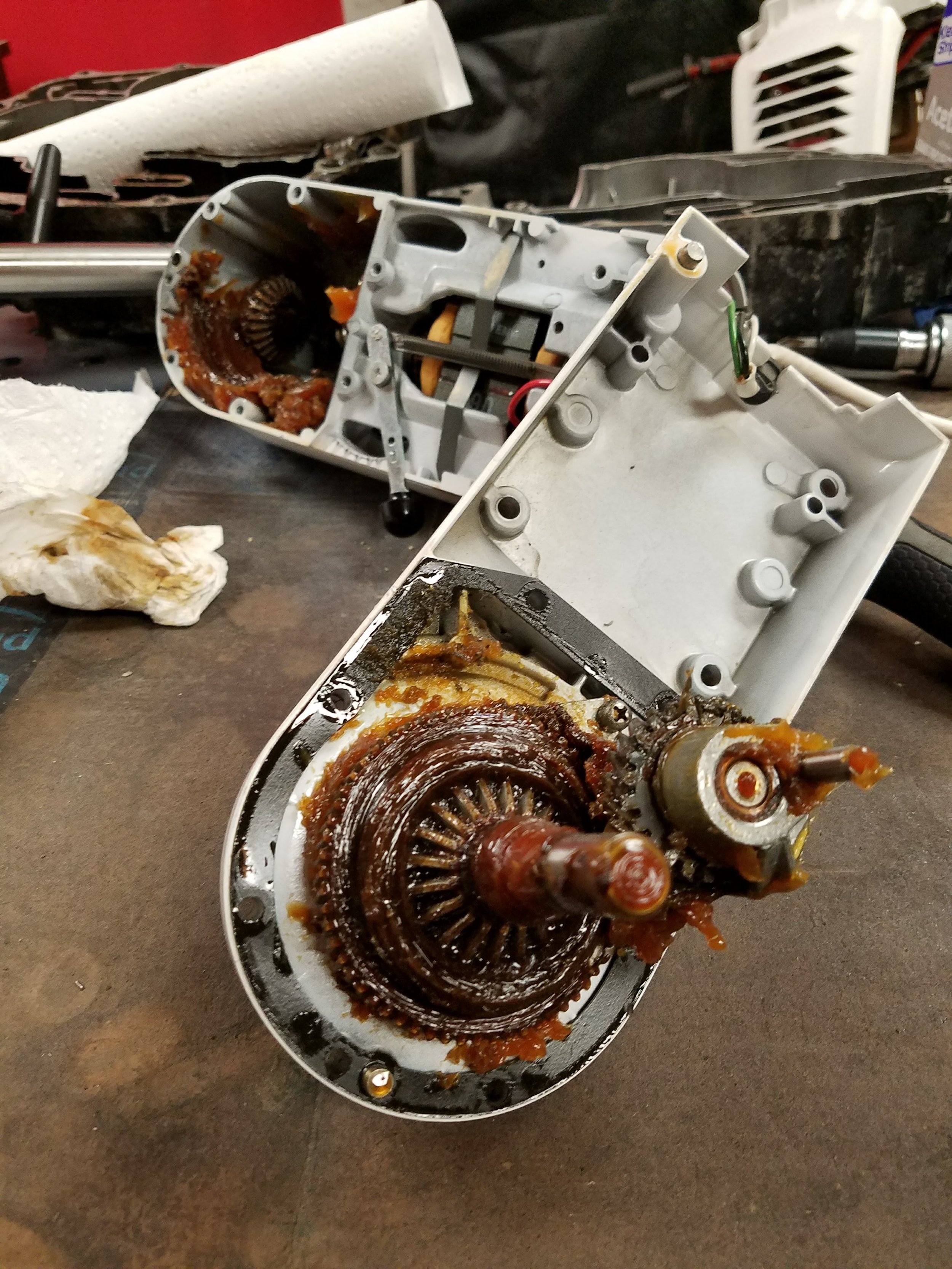

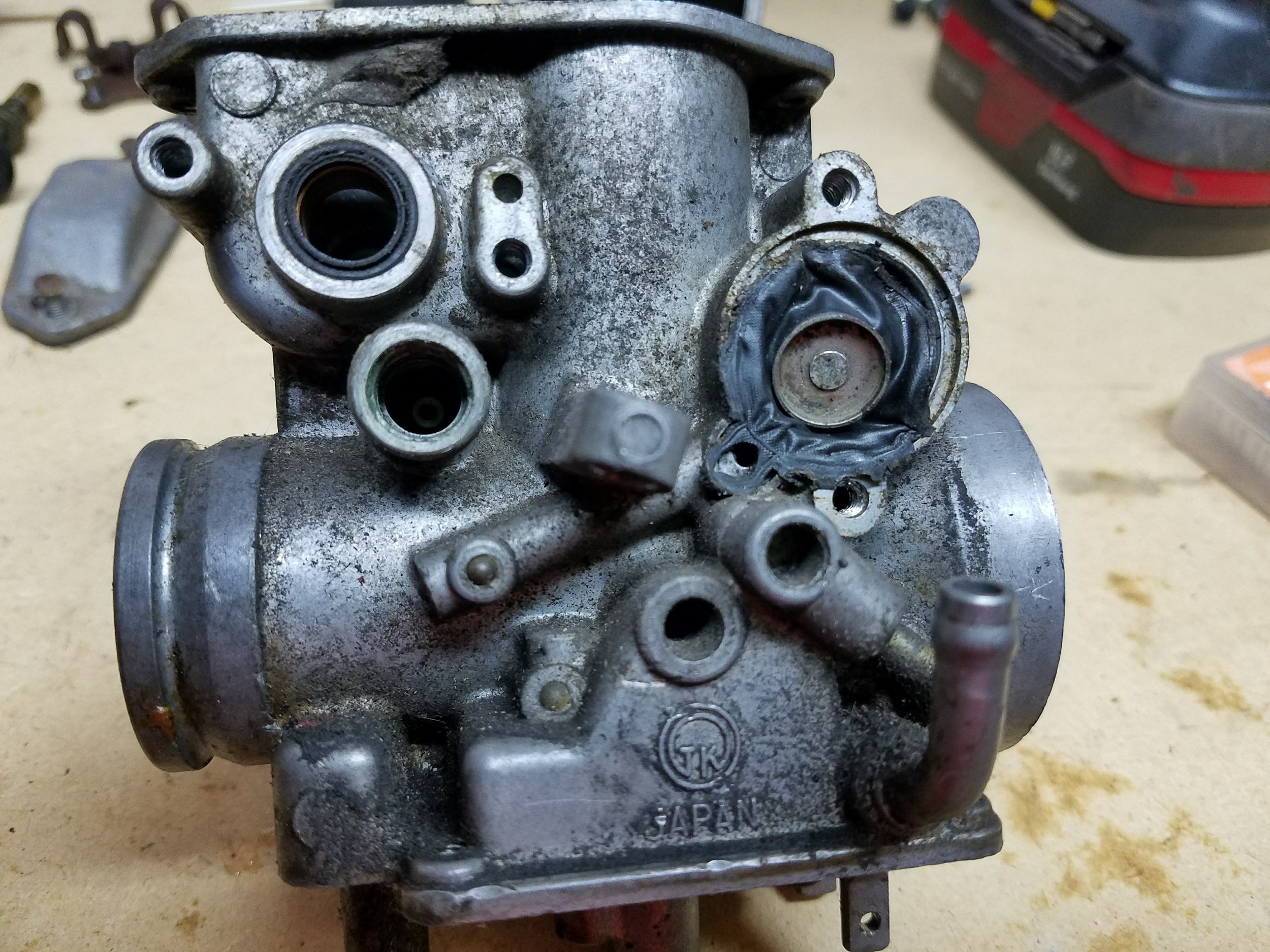

A lot of work has been done on this little 100cc two stroke bike too. I started by taking the carburetor off. What I found inside of it was something I’d never seen. Don’t know what this is or where it came from, but it was trash. So I found a replacement on eBay. Then had to diagnose a no spark condition. With some new points, the bike sparked strong and was ready to fire…in theory.

When I went to kick it I noticed the clutch didn’t work. So I took it apart, sanded down the metal plates, and that freed everything up to normal function.

Then I had to kick it about 500 times to get the water/oil/crap out of the crankcase. I’d kick, pull the plug, clean the plug, and repeat. Kick, pull plug, clean plug, repeat. Finally it came to life in a short spurt. I haven’t been able to get it to idle, but I think that’s a simple cleaning of the carburetor job. This one is about ready for market.

I also replaced the brake shoes front and back. A good example of why you should always replace old shoes is below- The linings delaminate and can cause huge problems when you're riding and they decide to get wedged in the drum.

KitchenAid-

I was bored and walking through goodwill. Found this thing for 25 American pesos. When I got it home, I noticed it didn’t work right. Made a racket and the planetary mixing arm wouldn’t turn all the time. Thanks to google and amazon, I had the $12 nylon gear in my hand 2 days later and now we have a mixer.

Soon:

BW200 will be back together and running. Maybe it goes to market, maybe not. Unsure just yet.

BW350 will be running and driving

Pinto will be rolling with a rear suspension under it again.

G4TR will be running. Off to market with it.

TW200 needs to be registered, tank needs to be painted.

KL400 needs to be ridden.

SL350 needs a motor rebuild

RT360 will go back together

DT250 needs an oil pump (have) a clutch problem diagnosed, and the exhaust re-welded.

Too many projects, but incremental progress…