March 2017

Greetings subscriber.

It’s been a short month so a proportional amount of work was accomplished.

KLX400- Was driven around and exercised a bit here and there. The battery has grown weak from sitting, but other than that, there have been no failures of any sort. It runs quite well and looks very green.

Falcon 8". Swapped out for a Maverick 8" later on.

Rear subframe without spacers

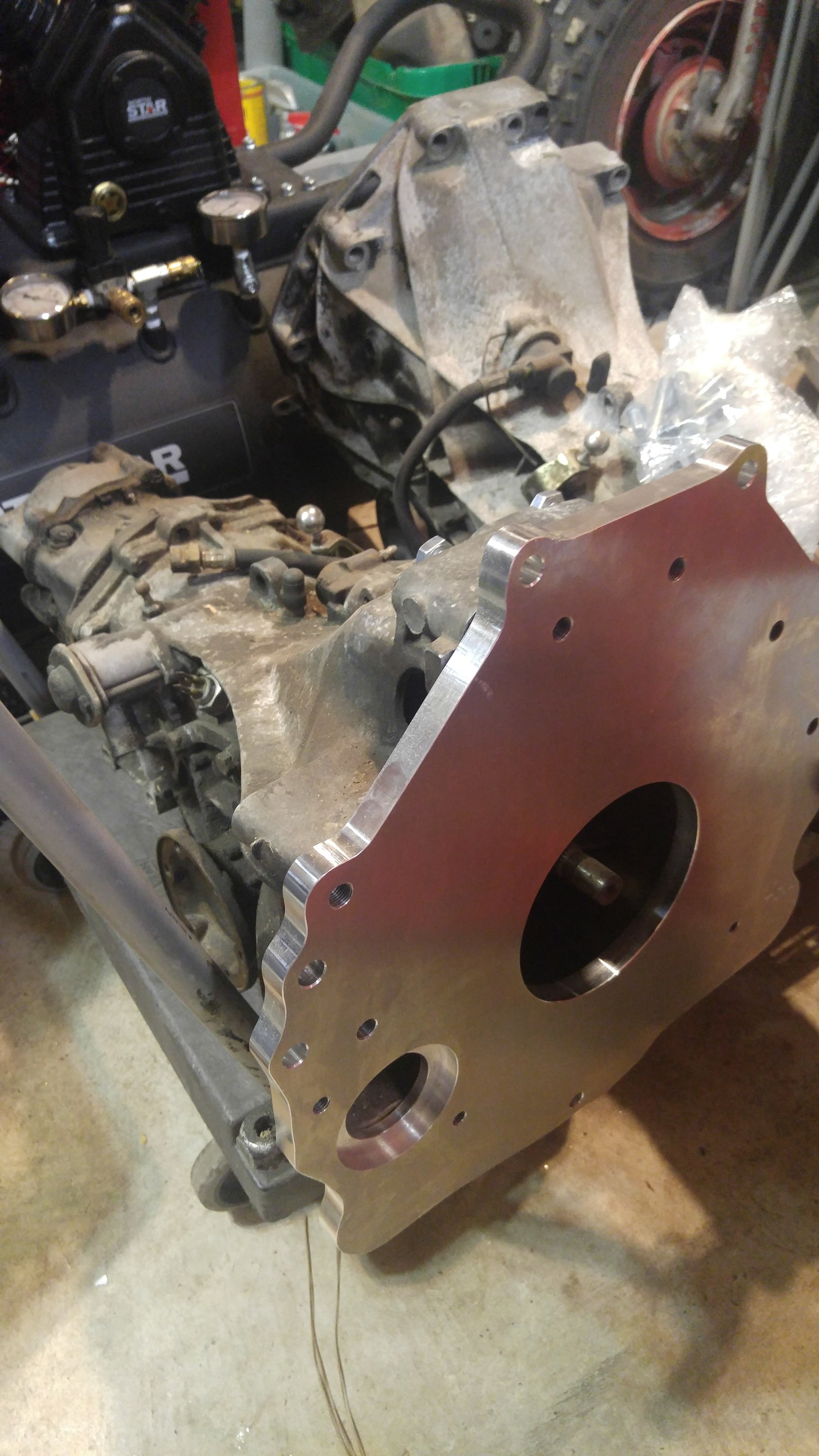

Pinto- The rear sub frame from the Porsche Carrera is complete and I’m hopeful it can be made to work with the transaxle and motor. The hubs are a strange proprietary Porsche bolt pattern. 5x130mm. Since this limits wheel choices, some aluminum adapters were ordered. They’re 1 inch thick and convert the Porsche lug pattern to 5x4.5” which is standard for all old Fords and many other models. The hubs are threaded to accept bolts, rather than to have protruding studs. Some lug bolts were purchased on eBay. They are en route.

Measurements were taken of the Pinto’s body to determine theoretical fitment of this rear end. The current Ford 8” rear end measures roughly 60” wide. The Porsche unit, disc to disc, is 69” wide.

Currently, the Maverick rear end has 5” spacers on each side to allow the wheels to clear. this is only because the cheapest wheel/tire combo I could find on craigslist was from a late model mustang. The top of the 18” wheel tucks inside the wheel well.

So, figure that the maverick rear end with spacers is 10” wider, and the two units are near identical in width, which seems compatible from a body width standpoint.

Once the spacers are secured to the hubs, efforts will be made to mount to engine/transaxle together and mock up fitment in the rear cradle. Fabrication will begin.

A huge part of the project, the transaxle to engine adapter, was ordered and received. Clutch parts still needed, but the kit came with the adapter, bolts, and a custom flywheel.

Got the transaxles as a pair. Hard to find these, so when they both showed up in Houston a few miles from work, I had to get both. Originally from an Audi 5000 front wheel drive car.

RT360- The bike was very hard to roll at first. Upon further inspection, the end of the brake cable was tied to the front brake hub lever. Tied. So I unbolted that and it rolls well now. That’s all I’ve done. It has barely moved. It’s the next motorcycle on the chopping block, however. Engine will be quickly gone through, main seals replaced, bit polished, carburetor cleaned. Going to try to not get too involved with this one. Though I say that every time…

BW350- found a long travel shock on eBay. Bike has mostly cosmetic issues. Not sure if it runs, but if not the culprit is likely the CDI box.

BW350 coming apart

BW Frame in red, TW in grey

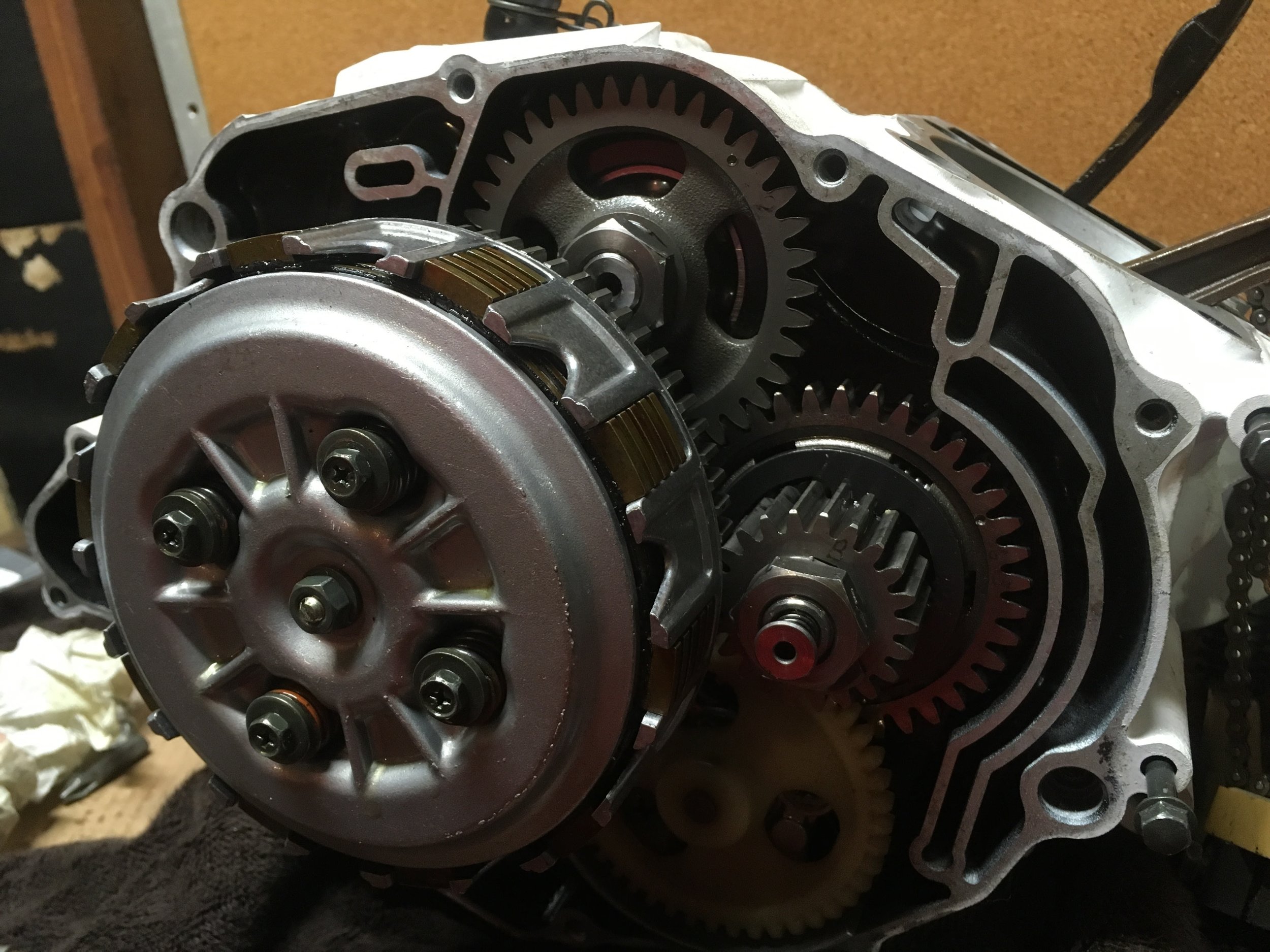

TW200- most of the months’ work was spent on this bike. The engine was put back together mostly with no hiccups. I had to grind out the ID of an output shaft spacer. Normally, there’s a kick starter idler gear in that spot. Since the TW doesn’t have a kick starter, a spacer goes in its place. The only function I can see it serving is to keep the oil galley in the shaft plugged up and keep oil pressure up. The spacer definitely fit on with a bit of wiggle room after I was done, so if there’s any issue with the motor it will be oil pressure and it will be because of that spacer.

Luckily, there is a bolt at the head specifically designed to provide access to the oil galley. If oil flows from that bolt hole, I will call that sufficient pressure.

The cam chain got stuck between the flywheel and crank gear, meaning it would slip. I had to remove the flywheel, loosen a cam chain tensioner, and reset the chain.

On the magneto side, one of the bolts that held the crank position sensor broke when removing (red Loctite will do that) so I tapped it out and placed a new bolt in.

Valve lapping

Engine is together, sealed up, sitting in the frame. With some fuel and electricity it should roar back to life. Was hoping to have that done before the month, but no such luck. By Friday we should have a running and driving machine. Catastrophes and victories will be reported next month.

Parts on hand that need to go on- Cycra hand guards, a slew of LED lights.

Bronco- Little was done in February but the first weekend in march will see the beginnings of body work. Front fenders are to be sanded and primed in a 2k epoxy primer. Frame will be cleaned up and painted with a rust-reactive paint (Rust Bullet brand). Sand Blasting will follow, after procuring a blaster. The air compressor I have should provide sufficient power, but I’ve fabricobbled a 3/8” valve and air fitting system that needs to be installed in the side of the tank. Currently cannot find a wrench big enough to get the inspection plug off. The only other air outlet on the tank is a high-flow ¼ fitting.

Honda Fit- needs an oil change.

March- Finish TW, Fix RT, Sell KLX, Sell TW, Bronco Body Work.

Til next time…